Over the last few months, we’ve had reports of lower pollution levels, clearer skies, and “the biggest carbon crash ever recorded”. Before the COVID-19 pandemic, it would have been hard to envision a world with such low carbon emissions. The insidious virus may have brought life as we knew it to a standstill, but it’s also made so many of us seek out more sustainable solutions for when we do go back outside.

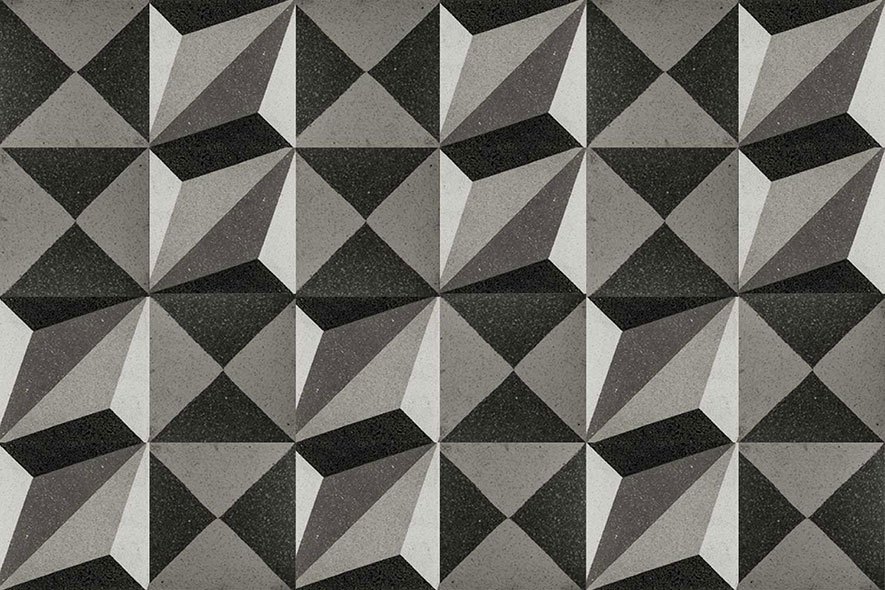

One such glimmer of hope for a better world comes by way of carbon tiles. The heavy smog that clogs Delhi skies, the grey fumes that sputter out of vehicles on our streets, the puffs of smoke that are pushed out of chimney stacks — these are carbon emissions created by burning fossil fuels. Graviky Labs, an award-winning MIT lab, realized that this air pollution could be put to use. They created Air-Ink, which can be used in lieu of black ink in pens, on textiles, and for printing. This pigment, captured from air pollution, also finds place in hand-pressed cement tiles from Carbon Craft Design. The idea is “to make climate change action accessible to all through art and architecture,” explains Tejas Sidnal, an architect and biomimetic designer, and the founder of Carbon Craft Design.

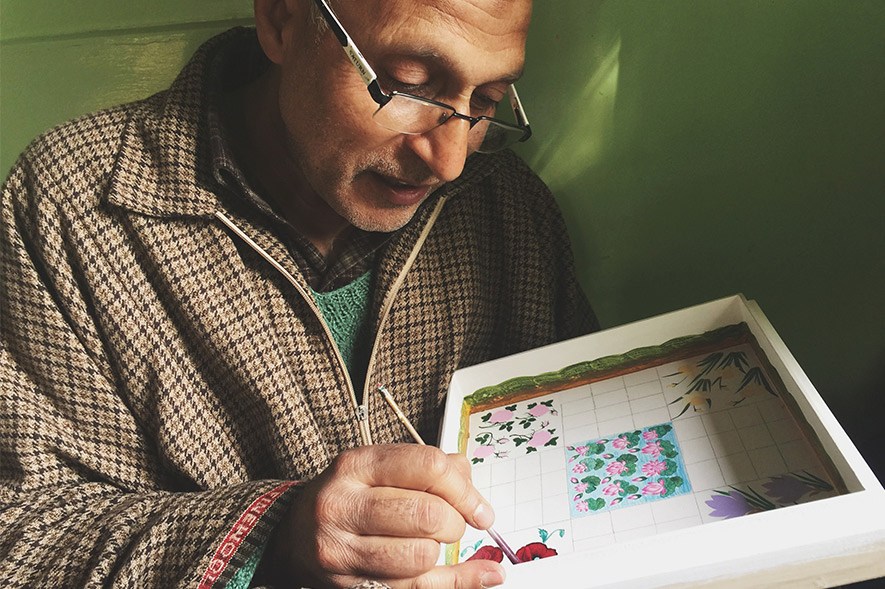

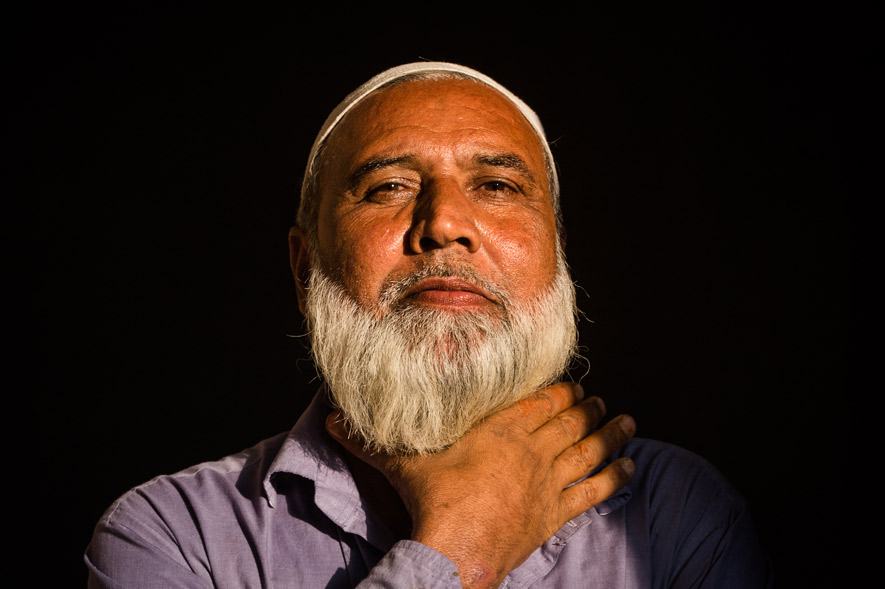

Sidnal has spent years employing biomimicry, a form of design and production of materials, structures, and systems that’s modelled on biological entities and processes, in his experiments and research. When he heard about Air-Ink and what Graviky Labs was doing, he knew he had to find an architectural use for this new, repurposed carbon.

In my conversation with Sidnal, his emphasis on scalability right from the start shines through. Across iterations, Sidnal and his team realized that they needed the architectural product to appeal to everyone. “We started to think, what is an architectural element that will help in a commercial Indian context, and also have design value to it?” It needed to be an element that could be seen, valued and appreciated. A couple of years and many failed experiments later, the carbon tile was born.

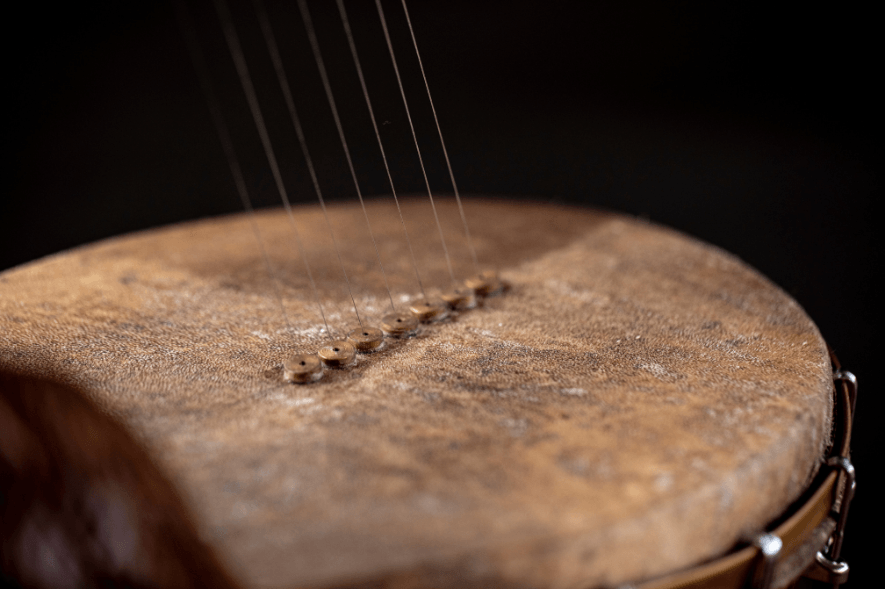

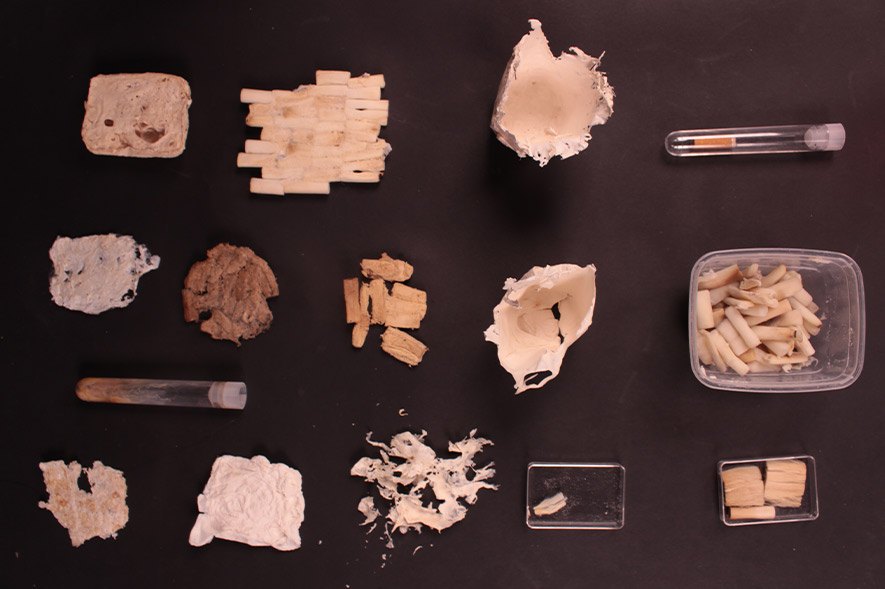

In Carbon Craft’s tiles, the captured carbon is used in the composition of the tile — mixed in with cement and natural materials like marble derivatives — but more specifically, as colour pigments for the patterns. But what’s the big deal, why do you need captured carbon for colour?

Everything from your favourite black t-shirt to your sleek black TV is typically made using ‘carbon black’, a fine carbon powder used as a pigment, which is made by burning fossil fuels in a controlled environment, Sidnal explains. “You use electricity [to burn the fuel], so you’re actually using a raw material, which again requires energy for it to be made crude, and then you burn it [for carbon].” All in all, using carbon black is not an energy-efficient choice. In comparison, working with the carbon particles from Air-Ink, which are practically plucked out of the air, require far less energy.

With captured carbon as the only pigment that’s used, Carbon Craft’s colour options are limited. “Air pollution is not a single source — it will be different when it comes from a material generator and from a brick kiln. Both have different sources [of fuel], so both will have different colours too. It’s difficult to standardize it,” Sidnal says. “That’s why we have limited shades of black and grey right now. Imagine if we add one more colour to this — like red, green or purple — how will you get that exact colour you require?” A similar challenge also arises if there’s a large order for a single project. All the tiles would need to match perfectly. For that to happen, the pollution used for the pigment would need to come from the same source. Sidnal is forthright about these challenges though — it’s been only a few months since they announced the carbon tile, so there’s a long way to go. “Scalability is what we wanted to always do, and we are trying to solve these issues,” he says. “If we have to make climate change action accessible to all, that’s the first thing we have to resolve.”

Sidnal also points out how crucial it is to ensure that the conversation around sustainability goes beyond just material used for the tile. Sure, these hand-pressed cement tiles have a low carbon footprint too (as opposed to vitrified tiles, “which need to be glazed at a very high temperature to be able to get that strength”), but there is also “a very rich culture and heritage” behind the process. “Once you get into a loop, there’s an entire cycle that you need to take care of. One choice changes your entire look towards a certain project,” he says. For instance, the team is currently working to limit carbon emissions during transportation by setting up manufacturing at various locations so that distances are cut short.

For Sidnal, architecture has a huge role to play in combating our current climate crisis. In our pre-pandemic world, construction was one of India’s largest contributors to carbon emissions. We may not know where exactly we’re headed at the moment, but just like carbon emissions can be upcycled, it’s heartening to know that a cleaner future is within reach.

Available at www.carboncraftdesign.com.

Fabiola Monteiro is Senior Editor at Paper Planes. She’s on Instagram at @fabiolamonteiro and on Twitter at @thefabmonteiro.

Tell us what you think? Drop us a line.